Have you ever marveled at how heavy-duty trucks perform amazing feats like heaving tons of cargo or towing massive vehicles? It’s all thanks to a small yet powerful device called a linear actuator.

A linear actuator’s job is to convert rotational motion into linear motion. It can help move things back and forth, up and down, or side to side with great force and precision. And that’s one reason why these devices find use in heavy-duty trucks.

In this article, we will explore why linear actuators are essential in heavy-duty trucks and what type of actuators are usually used in them.

Why Linear Actuators Are an Important Component in Heavy-Duty Truck

Those who own a heavy-duty truck understand that an efficient lifting and sliding system is key to dealing with bulky materials. Linear actuators allow heavy-duty trucks to lift loads by applying compression and tension forces as needed.

They are also accurate with precise movements. This makes operating a heavy-duty truck an enjoyable experience. But there’s more. Let’s take a closer look at how linear actuator bring benefits to heavy-duty trucks:

1. Improved Efficiency

Linear actuators themselves are efficient devices. Since they are so efficient, they improve the efficiency of the heavy-duty truck. This is crucial for the best performance of the trucks since they need reliable and precise control. Their accurate movement enables energy cost reduction and improves overall efficiency.

2. Increased Durability

Every component of a heavy-duty truck, including the linear actuator, must be durable. And linear actuators are designed for heavy-duty trucks to offer impressive load-bearing capabilities.

They also can handle shocks and vibrations without any impact on their performance or reliability over time.

3. Improved Safety

Linear actuators are built with safety in mind, so having them in heavy-duty trucks is a great way to make them safer. Also, you won’t have to worry about recurring repair costs or downtime. Heavy-duty linear actuators guarantee dependability and security for heavy-duty trucks. This provides peace of mind to truck drivers.

4. Adaptability to Harsh Environments

For heavy-duty trucks, navigating harsh terrain is a must. It requires resilience in every of its component. Linear actuators boast features like protective seals to keep moisture out.

They are built out of materials resistant to corrosion so they’re ready for whatever life throws their way. when operating under these challenging circumstances they’ll still perform without fail.

The Purpose of Actuator in Heavy-Duty Trucks

The world of heavy-duty trucking requires immense strength, endurance, and precision. Thankfully, linear actuators exist to provide these key capabilities. They allow for safe yet effective performance for daily operations.

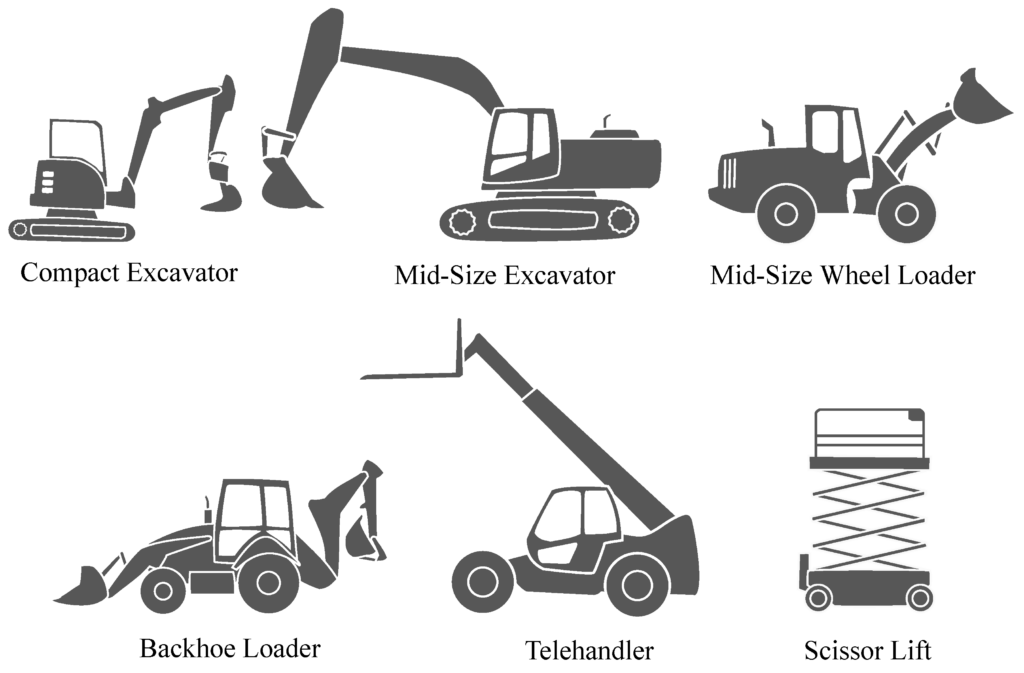

We know from experience the purpose of linear actuators in heavy trucks, from dump trucks to fire trucks. And here are a few:

For Unloading, Lifting, and Lowering Load

Heavy-duty trucks rely on linear actuators to manipulate the movement of their various components. Among such parts include: the bed, tailgate, ladder, boom, winch, and plow.

The linear actuator plays an essential role in lifting or lowering the bed of a dump truck, for instance. This movement makes unloading and retracting easy. It makes extending ladders on firetrucks to accommodate various situations a simple task. Also, these powerful devices also adapt their angle/direction toward diverse terrain demands.

For Balance and Stability of Trucks

Facilitating balance and stability is a critical function of linear actuators in trucks. These devices can deploy outriggers and stabilizers when lifting bulky loads. This allows them to provide much-needed support throughout such operations.

Besides aiding with balancing acts, they can also apply failsafe mechanisms like brakes/clamps. They help prevent unwanted movements along bumpy roads while transporting cargo.

To Control Steering and Braking Systems

The importance of linear actuators cannot be overstated. This is especially true when they manage critical functions like steering systems on large trucks. Due to their ability to provide fine-tuned control over essential systems, truck drivers can experience smoother handling.

And if an unexpected need arises for quick braking or stopping power due to an unforeseen event on the road? Linear actuators are there to support the quick deployment of emergency brake systems. An amazing feat for safeguarding both drivers and goods alike from harm.

For Controlling the Suspension System

Linear actuators come to our rescue with yet another application: controlling truck suspensions! These devices offer adjustable settings that cater to different road conditions. The result is a smoother driving experience. For those who transport goods frequently, linear actuators also ensure minimal damage to cargo. This is because they help reduce bumpiness and vibration from rugged terrains.

The Type of Actuators Used in Heavy Duty Trucks

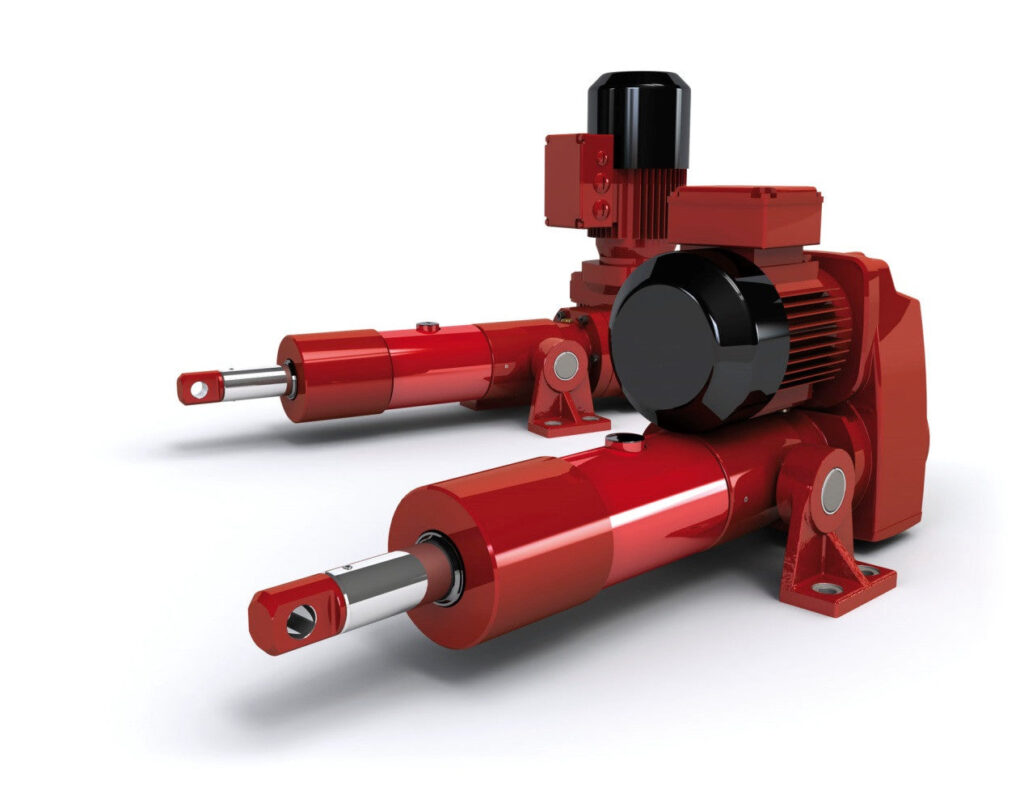

Linear actuation systems come in a variety of options based on their working principle. Amongst these options lie two particular favorites: hydraulic and electric linear actuators.

1. Hydraulic Linear Actuators

Hydraulic actuators use pressurized fluids to create straight-line motion. Unlike air, fluids cannot be compressed. This quality allows the hydraulic device to achieve enormous force to perform just about any load-handling task.

They are favored for their impressive force output, quick response times, and smooth operation. This makes them well-suited for handling extra-heavy weights or shifting large masses around with ease.

Yet, they are expensive and require regular maintenance, making them less practical for heavy trucks.

2. Electric Linear Actuators

Electric actuators rely on motorized components powered by electricity to execute linear movements. The standout feature of these devices is their ability to deliver reliable control with negligible noise levels. They are also easily combined with different systems, increasing their functionality even further.

Thus, it makes them an ideal choice when precise movement in a heavy truck is needed. And unlike hydraulic actuators, they do not require as much maintenance.

Conclusion

Heavy-duty trucking demands strength, endurance, and precision. Which is where linear actuators come into their own. They provide the necessary movements for heavy-duty trucks to perform their duties with ease. Be it unloading or lifting loads these versatile devices have you covered.

In the future, we can expect even more innovation in truck automation, where linear actuators are bound to play an essential part.